Friction Welding

FRICTION WELDING

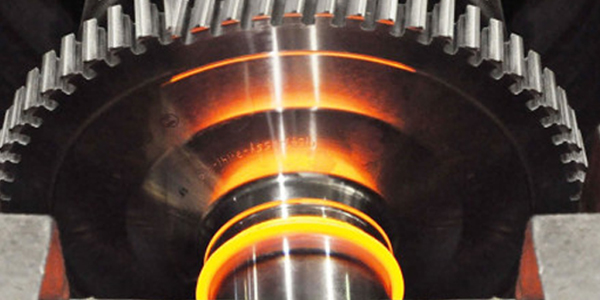

Friction welding refers to the method of welding by using the heat generated by the friction of the workpiece contact surface as the heat source to cause the workpiece to undergo plastic deformation under pressure.

Under the action of pressure, under the action of constant or incremental pressure and torque, the relative movement between the welding contact end faces generates frictional heat and plastic deformation heat on the friction surface and its vicinity, so that the temperature of its vicinity rises to The temperature range close to but generally lower than the melting point, the deformation resistance of the material is reduced, the plasticity is improved, and the oxide film at the interface is broken. Under the action of the upsetting pressure, the plastic deformation and flow of the material are accompanied by molecular diffusion and recrystallization at the interface. Solid-state welding method for realizing welding.

Minghe offers complete friction welding solutions for a vast range of die casting applications – with a large machine portfolio and additional support ranging from engineering to service. As the global leader in investment casting manufacturing, we take pride in offering only the best services on the market. Our passion for outstanding customer service leads our drive for excellency. To learn more about our services or discuss options for your next project, reach out to the team today.

The essence of friction welding

It is common for the metal surfaces of mechanical parts to bond and weld due to friction. In the process of metal cutting and high-speed rotation of the machine, it is often found that the surfaces of two metal parts are welded together due to friction and heat. For example: during turning, a built-up edge is generated on the turning tool; during drilling, the drill and the workpiece are often bonded together; the sliding bearing is stuck due to the burning of the shaft. Of course, these situations have always been accidents that people strive to avoid. Analyzed as a welding phenomenon, their process is not perfect, and the welding quality is not ideal.

However, through the analysis of these bonding and welding phenomena, it is helpful to understand the essence of friction welding.

The friction destroys the oxide film on the metal surface. The frictional heat generation reduces the strength of the metal but increases its plasticity. The friction surface metal produces plastic deformation and flow, which prevents the oxidation of the metal, promotes the mutual diffusion of weld metal atoms, and forms a strong welded joint. This is the essence of friction welding.

OThe Features of friction welding

Why friction welding is developing very rapidly at home and abroad, and its application is very wide, this is because it has a series of advantages. These advantages include the following aspects: